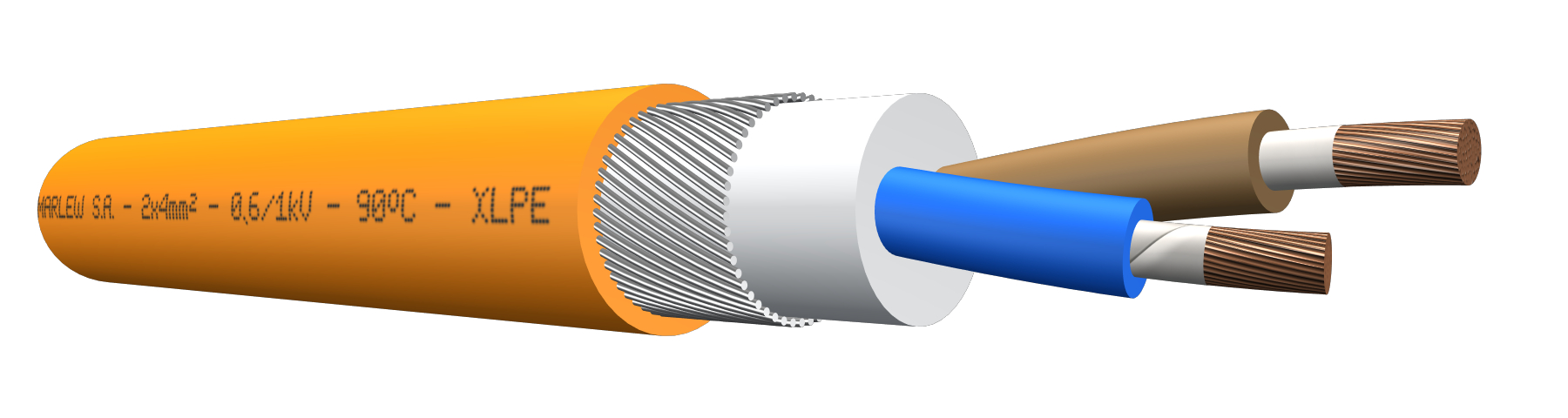

Clad series RP-H

Clad series RP-H

Steel wire armour

For fixed power distribution networks for alternating current (50/60Hz), for single-phase systems (220/110V), three-phase systems (380/190V) and systems with voltages up to 1kV. For Direct Current, used in systems with voltages up to 1.5kV Use in closed environments with a high concentration of people (airports, hospitals, trains, cinemas, shopping centers, tunnels) and in control rooms with electronic equipment sensitive to the exposure of corrosive gases. Installed in aerial trays, gutters or conduits, under roof or ladder under roof, buried in ducts or directly buried. It has additional mechanical protection.

Identification

| Standard | ||

|---|---|---|

| Sheath | Conductors | |

| 2 Conductors |  |   |

| 3 Conductors |  |    |

| 4 Conductors |  |     |

Instalation

Constructive variants

The information provided corresponds to the standard version. Special design can be manufactured to comply with reinforced circuit integrity, complying with other standards such as IEC 60331-1/2, EN 50200 or BS 6387.

ELECTRICAL CHARACTERISTICS

Resistances, reactance and intensity of admissible currents

| Nominal cross-section (mm²) | Electrical resistance in D.C. at 20°C (Ohm/km) | Electrical resistance in C.C. at 90°C (Ohm/km) | Inductive reactance at 50Hz (Ohm/Km) | Current-carrying capacity of cables in free air at 40°C as per IEC 364-5-523. In cable ladder or perforated cable trays (Ampere) | Current-carrying capacity of cables directly buried at 25°C soil temperature and soil thermal resistance of 1 km/W as per IEC 364-5-523 (Ampere) | |||

|---|---|---|---|---|---|---|---|---|

| Multiconductor (1) | 4 Conductors (2) | 2 Conductors | Multiconductor (3) | 2 Conductors | Multiconductor (3) | |||

|  |  |  |  |  | |||

| 1 | 19.5 | 24.86 | 0.107 | 0.114 | -- | -- | -- | -- |

| 1.5 | 13.3 | 16.96 | 0.100 | 0.107 | 23 | 20 | 32 | 28 |

| 2.5 | 7.98 | 10.18 | 0.093 | 0.100 | 31 | 28 | 44 | 37 |

| 4 | 4.95 | 6.31 | 0.088 | 0.095 | 43 | 36 | 57 | 48 |

| 6 | 3.3 | 4.21 | 0.083 | 0.090 | 54 | 47 | 72 | 61 |

| 10 | 1.91 | 2.44 | 0.078 | 0.085 | 74 | 65 | 97 | 83 |

| 16 | 1.21 | 1.54 | 0.075 | 0.082 | 100 | 86 | 129 | 107 |

| 25 | 0.78 | 0.99 | 0.075 | 0.083 | 128 | 109 | 166 | 141 |

| 35 | 0.554 | 0.707 | 0.073 | 0.081 | 160 | 137 | 200 | 168 |

| 50 | 0.386 | 0.493 | 0.073 | 0.080 | 195 | 166 | 238 | 199 |

| 70 | 0.272 | 0.348 | 0.071 | 0.079 | 250 | 213 | 292 | 243 |

| 95 | 0.206 | 0.264 | 0.070 | 0.077 | 304 | 257 | 351 | 293 |

| 120 | 0.161 | 0.207 | 0.070 | 0.077 | 354 | 299 | 399 | 333 |

| 150 | 0.129 | 0.167 | 0.070 | 0.077 | 409 | 345 | 448 | 373 |

| 185 | 0.106 | 0.138 | 0.070 | 0.077 | 468 | 394 | 508 | 425 |

| 240 | 0.0801 | 0.106 | 0.069 | 0.077 | 554 | 465 | 592 | 493 |

| 300 | 0.0641 | 0.0860 | 0.069 | 0.076 | 640 | 537 | 669 | 559 |

(1) Calculation of Inductive reactance valid for two-conductor and three-conductor cables. (2) Calculation of Inductive reactance valid for four-conductor cables. (3) The values of current-carrying capacity informed, correspond to three-conductor, four-conductor.

DIMENSIONS & WEIGHT

| Cable Formation N° Cond. x cross-section (mm²) | Diameter below armour mm | External diameter mm | Weight kg/km | Code |

|---|---|---|---|---|

| 2 x 1 | 8.4 | 13.0 | 313 | RP 0210 H |

| 2 x 1.5 | 9.0 | 13.6 | 343 | RP 0215 H |

| 2 x 2.5 | 9.9 | 14.5 | 394 | RP 0225 H |

| 2 x 4 | 10.9 | 15.5 | 459 | RP 0240 H |

| 2 x 6 | 12.1 | 16.7 | 540 | RP 0260 H |

| 2 x 10 | 14.2 | 19.7 | 847 | RP 2100 H |

| 2 x 16 | 16.5 | 22.0 | 1074 | RP 2160 H |

| 2 x 25 | 19.2 | 25.4 | 1538 | RP 2250 H |

| 2 x 35 | 21.2 | 27.4 | 1,842 | RP 2350 H |

| 2 x 50 | 24.6 | 30.8 | 2,331 | RP 2500 H |

| 2 x 70 | 29.0 | 35.6 | 3,040 | RP 2700 H |

| 2 x 95 | 33.4 | 41.3 | 4,177 | RP 2950 H |

| 2 x 120 | 36.7 | 44.8 | 4,982 | RP 21200 H |

| 2 x 150 | 41.4 | 49.7 | 5,956 | RP 21500 H |

| 2 x 185 | 45.6 | 55.3 | 7,527 | RP 21850 H |

| 2 x 240 | 51.9 | 62.2 | 9,543 | RP 22400 H |

| 2 x 300 | 58.7 | 69.2 | 11,565 | RP 23000 H |

| 3 x 1 | 8.9 | 13.5 | 337 | RP 0310 H |

| 3 x 1.5 | 9.6 | 14.2 | 372 | RP 0315 H |

| 3 x 2.5 | 10.6 | 15.2 | 432 | RP 0325 H |

| 3 x 4 | 11.6 | 16.2 | 511 | RP 0340 H |

| 3 x 6 | 12.9 | 17.5 | 610 | RP 0360 H |

| 3 x 10 | 15.1 | 20.6 | 964 | RP 3100 H |

| 3 x 16 | 17.7 | 23.2 | 1243 | RP 3160 H |

| 3 x 25 | 20.6 | 26.8 | 1,795 | RP 3250 H |

| 3 x 35 | 22.8 | 29.0 | 2,185 | RP 3350 H |

| 3 x 50 | 26.4 | 32.8 | 2,815 | RP 3500 H |

| 3 x 70 | 31.5 | 39.2 | 4,073 | RP 3700 H |

| 3 x 95 | 35.8 | 43.9 | 5,039 | RP 3950 H |

| 3 x 120 | 39.5 | 47.8 | 6,075 | RP 31200 H |

| 3 x 150 | 45.0 | 54.7 | 7,874 | RP 31500 H |

| 3 x 185 | 49.0 | 58.7 | 9,128 | RP 31850 H |

| 3 x 240 | 56.3 | 66.8 | 11,738 | RP 32400 H |

| 4 x 1 | 9.8 | 14.4 | 374 | RP 0410 H |

| 4 x 1.5 | 10.5 | 15.1 | 415 | RP 0415 H |

| 4 x 2.5 | 11.6 | 16.2 | 488 | RP 0425 H |

| 4 x 4 | 12.8 | 17.4 | 585 | RP 0440 H |

| 4 x 6 | 14.3 | 19.8 | 853 | RP 0460 H |

| 4 x 10 | 16.7 | 22.2 | 1119 | RP 4100 H |

| 4 x 16 | 19.6 | 25.8 | 1616 | RP 4160 H |

| 3 x 25 + 1 x 16 | 22.0 | 28.2 | 1,994 | RP 2516 H |

| 3 x 35 + 1 x 16 | 23.9 | 30.0 | 2,358 | RP 3516 H |

| 3 x 50 + 1 x 25 | 27.7 | 34.1 | 3,072 | RP 5025 H |

| 3 x 70 + 1 x 35 | 32.7 | 40.6 | 4,442 | RP 7035 H |

| 3 x 95 + 1 x 50 | 37.3 | 15.4 | 5,503 | RP 9550 H |

| 3 x 120 + 1 x 70 | 41.7 | 50.2 | 6,782 | RP 12070 H |

| 3 x 150 + 1 x 70 | 46.4 | 26.1 | 8,479 | RP 15070 H |

| 3 x 185 + 1 x 95 | 51.0 | 60.9 | 9,977 | RP 18595 H |

| 3 x 240 + 1 x 120 | 58.2 | 68.9 | 12,787 | RP 240120 H |