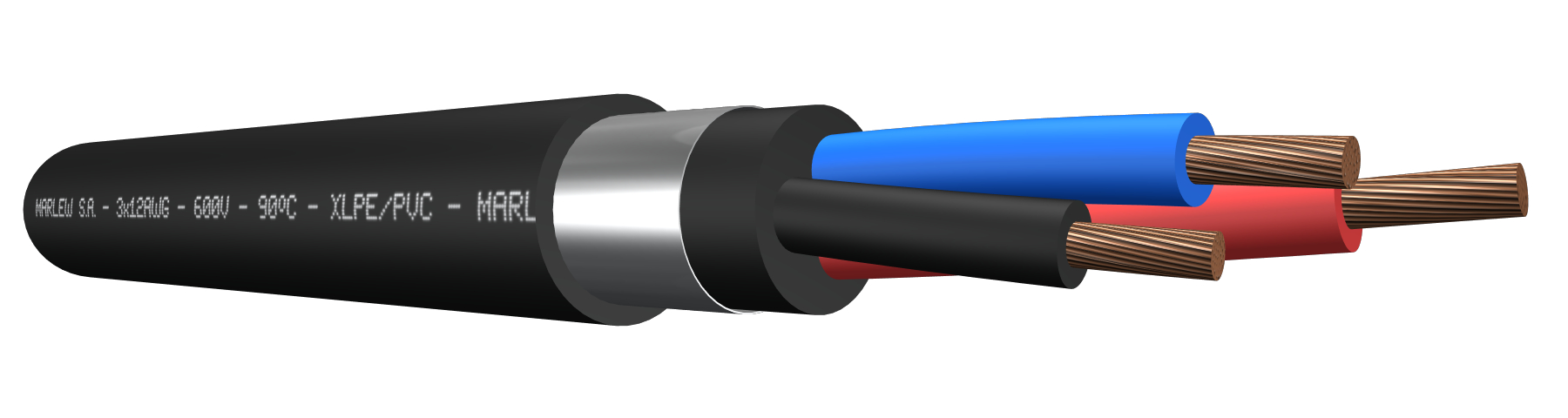

Clad series MLTC-FRV

Clad series MLTC-FRV

Steel tape armour

Fixed power distribution lines for the oil and gas insdustry (Midstream and Downstream) For Alternating Current (60Hz), for single-phase systems (110V), three-phase systems (190/210V) and systems with voltages up to 600V. Installed in aerial trays, gutters or conduits, under roof or ladder under roof, buried in ducts or directly buried. It has additional mechanical protection.

Identification

| Standard | ||

|---|---|---|

| Sheath | Conductors | |

| 1 Conductor |  |  |

| 2 Conductors |  |   |

| 3 Conductors |  |    |

| 4 Conductors |  |     |

Instalation

ELECTRICAL CHARACTERISTICS

Resistances, reactance and intensity of admissible currents

| Conductor’s gauge (AWG) | Flexible class conductors. Electrical resistance at 20°C en D.C. (Ohm/km) | Flexible class conductors. Electrical resistance in C.C. at 90°C (Ohm/km) | Reactancia inductiva a 60Hz (Ohm/Km) | Current-carrying capacity (6) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 Conductor (1) | Unipolar (2) | Unipolar (3) | Multiconductor (4) | 4 Conductors (5) | ||||||

| 1 Conductor | Multiconductor | 1 Conductor | Multiconductor |  |  |  |  |  |  | |

| 14 | 8.6 | 8.77 | 10.97 | 11.19 | -- | -- | -- | 0.098 | 0.105 | 25 |

| 12 | 5.41 | 5.52 | 6.90 | 7.04 | -- | -- | -- | 0.092 | 0.099 | 30 |

| 10 | 3.409 | 3.48 | 4.35 | 4.43 | -- | -- | -- | 0.086 | 0.093 | 40 |

| 8 | 2.144 | 2.19 | 2.73 | 2.79 | -- | -- | -- | 0.090 | 0.097 | 55 |

| 6 | 1.37 | 1.40 | 1.75 | 1.78 | -- | -- | -- | 0.084 | 0.091 | 75 |

| 4 | 0.863 | 0.880 | 1.10 | 1.12 | 0.130 | 0.173 | 0.115 | 0.080 | 0.087 | 95 |

| 2 | 0.545 | 0.556 | 0.696 | 0.709 | 0.122 | 0.166 | 0.108 | 0.077 | 0.084 | 130 |

| 1 | 0.43 | 0.439 | 0.549 | 0.560 | 0.120 | 0.163 | 0.105 | 0.078 | 0.085 | 145 |

| 1/0 | 0.344 | 0.351 | 0.440 | 0.448 | 0.118 | 0.162 | 0.104 | 0.076 | 0.083 | 170 |

| 2/0 | 0.274 | 0.279 | 0.351 | 0.358 | 0.114 | 0.158 | 0.100 | 0.074 | 0.081 | 195 |

| 3/0 | 0.217 | 0.221 | 0.278 | 0.284 | 0.112 | 0.156 | 0.098 | 0.072 | 0.080 | 225 |

| 4/0 | 0.172 | 0.175 | 0.222 | 0.226 | 0.109 | 0.153 | 0.095 | 0.071 | 0.079 | 260 |

| 250 | 0.147 | 0.150 | 0.190 | 0.194 | 0.108 | 0.152 | 0.094 | 0.072 | 0.079 | 290 |

| 300 | 0.123 | 0.125 | 0.160 | 0.163 | 0.106 | 0.190 | 0.091 | 0.071 | 0.078 | 320 |

| 350 | 0.105 | 0.107 | 0.138 | 0.140 | 0.104 | 0.148 | 0.090 | 0.070 | 0.078 | 350 |

| 400 | 0.0919 | 0.0937 | 0.121 | 0.124 | 0.103 | 0.146 | 0.088 | 0.070 | 0.077 | 380 |

| 450 | 0.0817 | 0.0833 | 0.109 | 0.111 | 0.101 | 0.144 | 0.086 | 0.069 | 0.076 | 405 |

| 500 | 0.0735 | 0.0750 | 0.0991 | 0.1011 | 0.099 | 0.143 | 0.085 | 0.068 | 0.076 | 430 |

(1) Three single conductor cables displayed in flat, in contact with each other. (2) Three single conductor cables displayed in flat, separated by 1 diameter between each other. (3) Three single-conductor cables displayed in a trefoil in contact with each other. (4) Calculation of Inductive reactance valid for two-conductor, three-conductor, and five-conductor cables. (5) Calculation of Inductive reactance valid for four-conductor cables. (6) Intensidad admisible en cables con hasta tres conductores instalados en conductos o directamente enterrados, a una temperatura ambiente de 30°C de acuerdo a tabla 310.15 (B)(16) del NFPA 70. A partir de 4 conductores se aplicó adicionalmente los factores de corrección para mas de 3 conductores de la tabla 310.15 (B)(3)(a) del NFPA70.

DIMENSIONS & WEIGHT

| Cable formation N° Cond. x gauge AWG | Diameter under armour mm | External diameter mm | Weight kg/km | Code |

|---|---|---|---|---|

| 1 x 4 | 9.8 | 14.4 | 364 | ML 0104 DRV |

| 1 x 2 | 11.3 | 15.8 | 491 | ML 0102 DRV |

| 1 x 1 | 12.7 | 17.2 | 588 | ML 0101 DRV |

| 1 x 1/0 | 14.3 | 18.8 | 722 | ML 11/0 DRV |

| 1 x 2/0 | 15.5 | 20.1 | 876 | ML 12/0 DRV |

| 1 x 3/0 | 16.8 | 21.3 | 1044 | ML 13/0 DRV |

| 1 x 4/0 | 18.9 | 24.2 | 1352 | ML 14/0 DRV |

| 1 x 250 | 20.0 | 25.3 | 1577 | ML 1250 DRV |

| 1 x 300 | 22.6 | 27.9 | 1777 | ML 1300 DRV |

| 1 x 350 | 23.4 | 28.7 | 2056 | ML 1350 DRV |

| 1 x 400 | 24.7 | 30.0 | 2284 | ML 1400 DRV |

| 1 x 450 | 25.6 | 30.9 | 2451 | ML 1450 DRV |

| 1 x 500 | 27.1 | 32.4 | 2784 | ML 1500 DRV |

| 2 x 10 | 10.5 | 13.9 | 330 | ML 0210 FRV |

| 2 x 8 | 14.4 | 17.8 | 516 | ML 0208 FRV |

| 2 x 6 | 16.5 | 19.8 | 683 | ML 0206 FRV |

| 2 x 4 | 18.7 | 22.8 | 940 | ML 0204 FRV |

| 2 x 2 | 21.6 | 25.7 | 1270 | ML 0202 FRV |

| 2 x 1 | 34.4 | 28.5 | 1546 | ML 0201 FRV |

| 2 x 1/0 | 26.3 | 30.4 | 1812 | ML 21/0 FRV |

| 2 x 2/0 | 29.8 | 33.9 | 2291 | ML 22/0 FRV |

| 2 x 3/0 | 32.3 | 37.6 | 3088 | ML 23/0 FRV |

| 2 x 4/0 | 36.6 | 42.7 | 3929 | ML 24/0 FRV |

| 2 x 250 | 38.7 | 44.8 | 4502 | ML 2250 FRV |

| 2 x 300 | 43.9 | 49.9 | 5221 | ML 2300 FRV |

| 2 x 350 | 45.6 | 51.6 | 5894 | ML 2350 FRV |

| 2 x 400 | 48.1 | 54.2 | 6527 | ML 2400 FRV |

| 2 x 450 | 49.9 | 56.0 | 6989 | ML 2450 FRV |

| 2 x 500 | 52.9 | 58.9 | 7875 | ML 2500 FRV |

| 3 x 12 | 9.9 | 13.3 | 294 | ML 0312 FRV |

| 3 x 10 | 11.3 | 14.6 | 379 | ML 0310 FRV |

| 3 x 8 | 15.4 | 18.7 | 591 | ML 0308 FRV |

| 3 x 6 | 17.6 | 20.9 | 803 | ML 0306 FRV |

| 3 x 4 | 20.1 | 24.2 | 1124 | ML 0304 FRV |

| 3 x 2 | 23.2 | 27.3 | 1550 | ML 0302 FRV |

| 3 x 1 | 26.2 | 30.3 | 1892 | ML 0301 FRV |

| 3 x 1/0 | 29.2 | 33.3 | 2325 | ML 31/0 FRV |

| 3 x 2/0 | 31.9 | 37.2 | 3206 | ML 32/0 FRV |

| 3 x 3/0 | 34.6 | 39.9 | 3802 | ML 33/0 FRV |

| 3 x 4/0 | 39.3 | 45.4 | 4855 | ML 34/0 FRV |

| 3 x 250 | 41.6 | 47.6 | 5622 | ML 3250 FRV |

| 3 x 300 | 47.1 | 53.2 | 6461 | ML 3300 FRV |

| 3 x 350 | 48.9 | 55.0 | 7386 | ML 3350 FRV |

| 3 x 400 | 51.7 | 57.8 | 8203 | ML 3400 FRV |

| 3 x 450 | 53.7 | 59.7 | 8800 | ML 3450 FRV |

| 3 x 500 | 56.8 | 63.7 | 10081 | ML 3500 FRV |

| 4 x 14 | 9.8 | 13.1 | 272 | ML 0414 FRV |

| 4 x 12 | 10.9 | 14.3 | 340 | ML 0412 FRV |

| 4 x 10 | 12.4 | 15.8 | 444 | ML 0410 FRV |

| 4 x 8 | 17.0 | 20.3 | 694 | ML 0408 FRV |

| 4 x 6 | 19.4 | 23.5 | 1000 | ML 0406 FRV |

| 4 x 4 | 22.2 | 26.3 | 1355 | ML 0404 FRV |

| 4 x 2 | 25.7 | 29.8 | 1891 | ML 0402 FRV |

| 4 x 1 | 30.1 | 34.2 | 2402 | ML 0401 FRV |

| 4 x 1/0 | 32.4 | 37.7 | 3214 | ML 41/0 FRV |

| 4 x 2/0 | 35.4 | 40.7 | 3904 | ML 42/0 FRV |

| 4 x 3/0 | 38.3 | 44.4 | 4736 | ML 43/0 FRV |

| 4 x 4/0 | 43.6 | 49.7 | 5961 | ML 44/0 FRV |

| 4 x 250 | 46.2 | 52.2 | 6942 | ML 4250 FRV |

| 4 x 300 | 52.4 | 58.4 | 7952 | ML 4300 FRV |

| 4 x 350 | 54.4 | 60.5 | 9147 | ML 4350 FRV |

| 4 x 400 | 57.6 | 64.4 | 10291 | ML 4400 FRV |

| 4 x 450 | 59.7 | 66.5 | 11049 | ML 4450 FRV |

| 4 x 500 | 63.3 | 70.1 | 12540 | ML 4500 FRV |