Clad series MH-H

Clad series MH-H

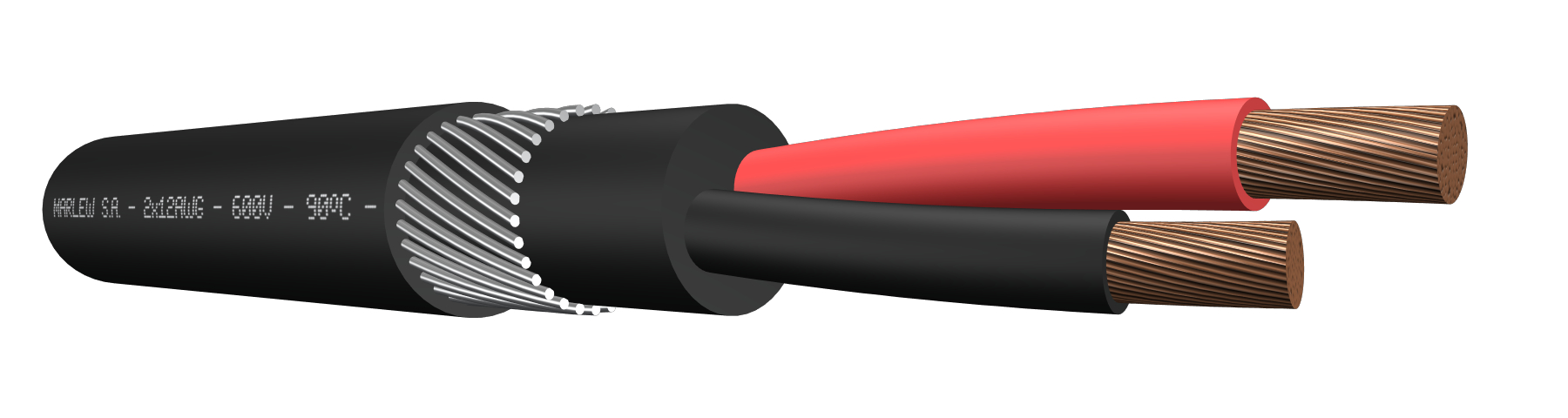

Steel wire armour

Fixed power distribution networks in closed environments with a high concentration of people (airports, hospitals, trains, cinemas, shopping malls, tunnels) and in control rooms with electronic equipment sensitive to exposure to corrosive gases. For Alternating Current (60Hz), for single-phase systems (110V), three-phase systems (190/210V) and systems with voltages up to 600V. Installed in conduits, trays, cable ladders, in direct open air or indoors, buried in a trench or in ducts. It has additional mechanical protection.

Identification

| Standard | ||

|---|---|---|

| Sheath | Conductors | |

| 2 Conductors |  |   |

| 3 Conductors |  |    |

| 4 Conductors |  |     |

Instalation

ELECTRICAL CHARACTERISTICS

Resistances, reactance and intensity of admissible currents

| Conductor’s gauge (AWG) | Flexible class conductors. Electrical resistance at 20°C en D.C. (Ohm/km) | Flexible class conductors. Electrical resistance in C.C. at 90°C (Ohm/km) | Reactancia inductiva a 60Hz (Ohm/Km) | Current-carrying capacity (6) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 Conductor (1) | Unipolar (2) | Unipolar (3) | Multiconductor (4) | 4 Conductors (5) | ||||||

| 1 Conductor | Multiconductor | 1 Conductor | Multiconductor |  |  |  |  |  |  | |

| 14 | 8.6 | 8.77 | 10.97 | 11.19 | 0.136 | 0.179 | 0.121 | 0.098 | 0.105 | 25 |

| 12 | 5.41 | 5.52 | 6.9 | 7.04 | 0.127 | 0.171 | 0.113 | 0.092 | 0.099 | 30 |

| 10 | 3.409 | 3.48 | 4.35 | 4.43 | 0.119 | 0.163 | 0.105 | 0.086 | 0.093 | 40 |

| 8 | 2.144 | 2.19 | 2.73 | 2.79 | 0.118 | 0.162 | 0.104 | 0.09 | 0.097 | 55 |

| 6 | 1.37 | 1.4 | 1.75 | 1.78 | 0.11 | 0.154 | 0.096 | 0.084 | 0.091 | 75 |

| 4 | 0.863 | 0.88 | 1.1 | 1.12 | 0.105 | 0.149 | 0.09 | 0.08 | 0.087 | 95 |

| 2 | 0.545 | 0.556 | 0.696 | 0.709 | 0.1 | 0.144 | 0.086 | 0.077 | 0.084 | 130 |

| 1 | 0.43 | 0.439 | 0.549 | 0.56 | 0.104 | 0.148 | 0.09 | 0.078 | 0.085 | 145 |

| 1/0 | 0.344 | 0.351 | 0.44 | 0.448 | 0.101 | 0.145 | 0.087 | 0.076 | 0.083 | 170 |

| 2/0 | 0.274 | 0.279 | 0.351 | 0.358 | 0.098 | 0.142 | 0.084 | 0.074 | 0.081 | 195 |

| 3/0 | 0.217 | 0.221 | 0.278 | 0.284 | 0.096 | 0.139 | 0.081 | 0.072 | 0.08 | 225 |

| 4/0 | 0.172 | 0.175 | 0.222 | 0.226 | 0.094 | 0.137 | 0.079 | 0.071 | 0.079 | 260 |

| 250 | 0.147 | 0.15 | 0.19 | 0.194 | 0.097 | 0.141 | 0.083 | 0.072 | 0.079 | 290 |

| 300 | 0.123 | 0.125 | 0.16 | 0.163 | 0.095 | 0.139 | 0.08 | 0.071 | 0.078 | 320 |

| 350 | 0.105 | 0.107 | 0.138 | 0.14 | 0.094 | 0.138 | 0.079 | 0.07 | 0.078 | 350 |

| 400 | 0.0919 | 0.0937 | 0.121 | 0.124 | 0.093 | 0.136 | 0.078 | 0.07 | 0.077 | 380 |

| 450 | 0.0817 | 0.0833 | 0.109 | 0.111 | 0.091 | 0.135 | 0.077 | 0.069 | 0.076 | 405 |

| 500 | 0.0735 | 0.075 | 0.0991 | 0.1011 | 0.091 | 0.134 | 0.076 | 0.068 | 0.076 | 430 |

(1) Three single conductor cables displayed in flat, in contact with each other. (2) Three single conductor cables displayed in flat, separated by 1 diameter between each other. (3) Three single-conductor cables displayed in a trefoil in contact with each other. (4) Calculation of Inductive reactance valid for two-conductor, three-conductor, and five-conductor cables. (5) Calculation of Inductive reactance valid for four-conductor cables. (6) Current-carrying capacity of cables with up to three conductors, installed in ducts or directly buried, up to an ambient temperature of 30ºC, according to chart 310.15 (B)(16) of the NFPA 70. As from four-conductors, we’ve additionally applied the correction factor for more than three conductors from the chart 310.15 (B)(3)(a) of the NFPA70.

| Cable formation N° Cond. x gauge AWG/MCM | Diameter under armour mm | External diameter mm | Weight kg/km | Code |

|---|---|---|---|---|

| 2x14 | 10.8 | 15.8 | 518 | MH 0214 H |

| 2x12 | 11.7 | 16.7 | 583 | MH 0212 H |

| 2x10 | 12.9 | 18.0 | 671 | MH 0210 H |

| 2x8 | 16.1 | 22.6 | 1077 | MH 0208 H |

| 2x6 | 18.1 | 24.6 | 1297 | MH 0206 H |

| 2x4 | 20.4 | 26.9 | 1583 | MH 0204 H |

| 2x2 | 24.1 | 30.6 | 2075 | MH 0202 H |

| 2x1 | 26.8 | 34.4 | 2708 | MH 0201 H |

| 2x1/0 | 28.7 | 36.3 | 3055 | MH 21/0 H |

| 2x2/0 | 31.9 | 39.5 | 3682 | MH 22/0 H |

| 2x3/0 | 34.4 | 42.8 | 4296 | MH 23/0 H |

| 2x4/0 | 38.8 | 48.1 | 5592 | MH 24/0 H |

| 2x250 | 40.9 | 50.2 | 6238 | MH 2250 H |

| 2x300 | 46.0 | 55.3 | 7161 | MH 2300 H |

| 2x350 | 47.7 | 57.1 | 7895 | MH 2350 H |

| 2x400 | 50.3 | 59.6 | 8625 | MH 2400 H |

| 2x450 | 52.0 | 62.2 | 9232 | MH 2450 H |

| 2x500 | 55.0 | 65.1 | 10092 | MH 2500 H |

| 3x14 | 11.3 | 16.3 | 555 | MH 0314 H |

| 3x12 | 12.3 | 17.4 | 632 | MH 0312 H |

| 3x10 | 13.6 | 18.7 | 747 | MH 0310 H |

| 3x8 | 17.0 | 23.5 | 1185 | MH 0308 H |

| 3x6 | 19.3 | 25.8 | 1469 | MH 0306 H |

| 3x4 | 21.7 | 28.2 | 1837 | MH 0304 H |

| 3x2 | 25.6 | 33.2 | 2674 | MH 0302 H |

| 3x1 | 28.6 | 36.2 | 3170 | MH 0301 H |

| 3x1/0 | 31.4 | 39.0 | 3689 | MH 31/0 H |

| 3x2/0 | 34.1 | 42.4 | 4435 | MH 32/0 H |

| 3x3/0 | 36.7 | 46.1 | 5510 | MH 33/0 H |

| 3x4/0 | 41.4 | 50.8 | 6679 | MH 34/0 H |

| 3x250 | 43.7 | 53.0 | 7571 | MH 3250 H |

| 3x300 | 49.2 | 58.6 | 8627 | MH 3300 H |

| 3x350 | 51.1 | 60.4 | 9614 | MH 3350 H |

| 3x400 | 53.8 | 64.0 | 10527 | MH 3400 H |

| 3x450 | 55.8 | 65.9 | 11130 | MH 3450 H |

| 3x500 | 58.9 | 69.1 | 12276 | MH 3500 H |

| 4x14 | 12.2 | 17.2 | 612 | MH 0414 H |

| 4x12 | 13.3 | 18.4 | 702 | MH 0412 H |

| 4x10 | 14.8 | 19.8 | 849 | MH 0410 H |

| 4x8 | 18.6 | 25.1 | 1351 | MH 0408 H |

| 4x6 | 21.1 | 27.6 | 1691 | MH 0406 H |

| 4x4 | 24.6 | 31.1 | 2216 | MH 0404 H |

| 4x2 | 28.1 | 35.7 | 3143 | MH 0402 H |

| 4x1 | 32.2 | 39.8 | 3885 | MH 0401 H |

| 4x1/0 | 34.5 | 42.8 | 4493 | MH 41/0 H |

| 4x2/0 | 37.5 | 46.8 | 5678 | MH 42/0 H |

| 4x3/0 | 40.4 | 49.8 | 6537 | MH 43/0 H |

| 4x4/0 | 45.7 | 55.1 | 8002 | MH 44/0 H |

| 4x250 | 48.3 | 57.6 | 9116 | MH 4250 H |

| 4x300 | 54.5 | 64.6 | 10345 | MH 4300 H |

| 4x350 | 56.5 | 66.7 | 11525 | MH 4350 H |

| 4x400 | 59.6 | 69.8 | 12546 | MH 4400 H |

| 2x10+G10 | 13.6 | 18.7 | 747 | MH 0210 0110 H |

| 2x8+G10 | 16.5 | 23.0 | 1121 | MH 0208 0110 H |

| 2x6+G8 | 19.5 | 26.0 | 1440 | MH 0206 0108 H |

| 2x4+G8 | 21.0 | 27.5 | 1668 | MH 0204 0108 H |

| 2x2+G6 | 24.7 | 31.2 | 2201 | MH 0202 0106 H |

| 2x1+G6 | 26.8 | 34.4 | 2792 | MH 0201 0106 H |

| 2x1/0+G6 | 28.7 | 36.3 | 3139 | MH 21/0 0106 H |

| 2x2/0+G6 | 31.9 | 39.5 | 3766 | MH 22/0 0106 H |

| 2x3/0+G4 | 34.4 | 42.8 | 4430 | MH 23/0 0104 H |

| 2x4/0+G4 | 38.8 | 48.1 | 5726 | MH 24/0 0104 H |

| 2x250+G4 | 40.9 | 50.2 | 6372 | MH 2250 0104 H |

| 2x300+G3 | 46.0 | 55.3 | 7338 | MH 2300 0103 H |

| 2x350+G3 | 47.7 | 57.1 | 8072 | MH 2350 0103 H |

| 2x400+G3 | 50.3 | 59.6 | 8803 | MH 2400 0103 H |

| 2x450+G2 | 52.0 | 62.2 | 9446 | MH 2450 0102 H |

| 2x500+G2 | 55.0 | 65.1 | 10307 | MH 2500 0102 H |

| 2x550+G2 | 60.4 | 71.8 | 12291 | MH 2550 0102 H |

| 2x600+G2 | 61.3 | 72.7 | 12880 | MH 2600 0102 H |

| 3x10+G10 | 14.8 | 19.8 | 849 | MH 0310 0110 H |

| 3x8+G10 | 17.7 | 24.2 | 1256 | MH 0308 0110 H |

| 3x6+G8 | 20.5 | 27.0 | 1605 | MH 0306 0108 H |

| 3x4+G8 | 22.5 | 29.0 | 1940 | MH 0304 0108 H |

| 3x2+G6 | 26.5 | 34.1 | 2861 | MH 0302 0106 H |

| 3x1+G6 | 29.1 | 36.7 | 3278 | MH 0301 0106 H |

| 3x1/0+G6 | 31.5 | 39.1 | 3778 | MH 31/0 0106 H |

| 3x2/0+G6 | 33.8 | 41.4 | 4420 | MH 32/0 0106 H |

| 3x3/0+G4 | 36.7 | 46.0 | 5636 | MH 33/0 0104 H |

| 3x4/0+G4 | 41.6 | 51.0 | 6824 | MH 34/0 0104 H |

| 3x250+G4 | 43.7 | 53.0 | 7708 | MH 3250 0104 H |

| 3x300+G3 | 49.2 | 58.6 | 8807 | MH 3300 0103 H |

| 3x350+G3 | 51.1 | 60.4 | 9795 | MH 3350 0103 H |

| 3x400+G3 | 53.8 | 64.0 | 10709 | MH 3400 0103 H |

| 3x450+G2 | 55.8 | 65.9 | 11348 | MH 3450 0102 H |

| 3x500+G2 | 58.9 | 69.1 | 12496 | MH 3500 0102 H |

| 4x8+G10 | 19.4 | 25.9 | 1447 | MH 0408 0110 H |

| 4x6+G8 | 22.5 | 29.0 | 1853 | MH 0406 0108 H |

| 4x4+G8 | 25.7 | 33.3 | 2619 | MH 0404 0108 H |

| 4x2+G6 | 29.4 | 37.0 | 3349 | MH 0402 0106 H |

| 4x1+G6 | 33.2 | 40.8 | 4048 | MH 0401 0106 H |

| 4x1/0+G6 | 35.2 | 44.5 | 5005 | MH 41/0 0106 H |

| 4x2/0+G6 | 37.9 | 47.2 | 5780 | MH 42/0 0106 H |

| 4x3/0+G4 | 41.1 | 50.5 | 6752 | MH 43/0 0104 H |

| 4x4/0+G4 | 47.1 | 56.4 | 8242 | MH 44/0 0104 H |

| 4x250+G4 | 49.1 | 58.5 | 9338 | MH 4250 0104 H |

| 4x300+G3 | 55.1 | 65.2 | 10562 | MH 4300 0103 H |

| 4x350+G3 | 56.8 | 66.9 | 11723 | MH 4350 0103 H |

| 4x400+G3 | 59.6 | 69.8 | 12728 | MH 4400 0103 H |

| 3x8+N10+G10 | 18.6 | 25.1 | 1356 | MH 0308 0210 H |

| 3x6+N8+G8 | 22.0 | 28.5 | 1770 | MH 0306 0208 H |

| 3x4+N8+G8 | 24.6 | 31.1 | 2163 | MH 0304 0208 H |

| 3x2+N6+G6 | 28.0 | 35.6 | 3075 | MH 0302 0206 H |

| 3x1+N6+G6 | 31.0 | 38.6 | 3566 | MH 0301 0206 H |

| 3x1/0+N6+G6 | 32.5 | 40.1 | 4012 | MH 31/0 0206 H |

| 3x2/0+N6+G6 | 34.5 | 42.9 | 4649 | MH 32/0 0206 H |

| 3x3/0+N4+G4 | 37.8 | 47.1 | 5879 | MH 33/0 0204 H |

| 3x4/0+N4+G4 | 41.3 | 50.7 | 6917 | MH 34/0 0204 H |

| 3x250+N4+G4 | 43.0 | 52.3 | 7721 | MH 3250 0204 H |

| 3x300+N3+G3 | 48.0 | 57.4 | 8767 | MH 3300 0203 H |

| 3x350+N3+G3 | 49.4 | 58.8 | 9708 | MH 3350 0203 H |

| 3x400+N3+G3 | 51.5 | 60.9 | 10517 | MH 3400 0203 H |

| 3x450+N2+G2 | 53.6 | 63.7 | 11308 | MH 3450 0202 H |

| 3x500+N2+G2 | 56.0 | 66.1 | 12364 | MH 3500 0202 H |

| 4x14+G14 | 13.1 | 18.2 | 671 | MH 0514 H |

| 4x12+G12 | 14.4 | 19.4 | 785 | MH 0512 H |

| 4x10+G10 | 16.0 | 22.5 | 1116 | MH 0510 H |

| 4x8+G8 | 20.3 | 26.8 | 1523 | MH 0508 H |

| 4x6+G6 | 23.1 | 29.6 | 1937 | MH 0506 H |

| 4x4+G4 | 26.9 | 34.5 | 2802 | MH 0504 H |

| 4x2+G2 | 31.6 | 39.2 | 3712 | MH 0502 H |

| 4x1+G1 | 35.3 | 44.7 | 4906 | MH 0501 H |

| 4x1/0+G1/0 | 37.8 | 47.2 | 5586 | MH 51/0 H |

| 4x2/0+G2/0 | 41.2 | 50.5 | 6569 | MH 52/0 H |

| 4x3/0+G3/0 | 44.5 | 53.8 | 7590 | MH 53/0 H |

| 4x4/0+G4/0 | 50.4 | 59.8 | 9357 | MH 54/0 H |

| 4x250+G250 | 53.2 | 63.3 | 10730 | MH 5250 H |

| 4x300+G300 | 60.1 | 71.5 | 13110 | MH 5300 H |