series FFfr U(TH)U

series FFfr U(TH)U

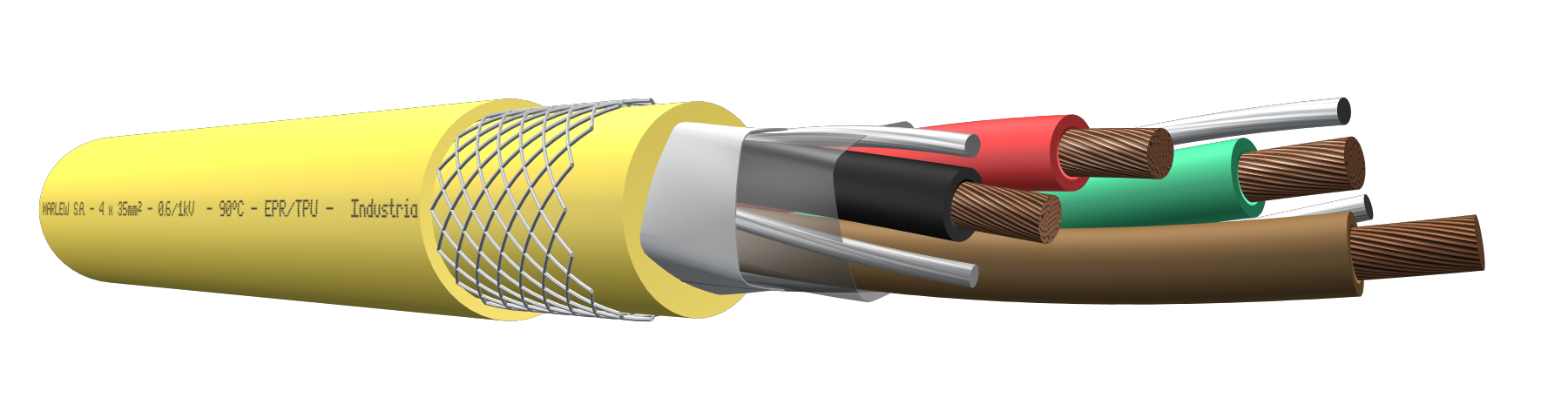

Flexible cables for winding in harsh environments

These type of cables are required for extra-heavy duty industrial use. These are power cables, reinforced portable low voltage, to be used in mining developments for heavy mobile equipment such as drag cables, shovels, drills and power feeders. This type of cable is required for extra-heavy duty industrial use. In oil fields it is used for feeding mobile drilling equipment, and in general for mobile outdoor installations with vertical and horizontal movement. It can withstand, while fixed or in movement, all types of efforts: traction, torsion, and flexion; caused by standard cable winding equipment. It counts with plastic materials which provide suitable protection against chemical products, harsh environment, tear and impacts.

Identification

| Standard | ||

|---|---|---|

| Sheath | Conductors | |

| 4 Conductors |  |     |

Instalation

Constructive variants

The information provided corresponds to the standard version, and different alternatives of colour armour.

ELECTRICAL CHARACTERISTICS, DIMENSIONS & WEIGHT

| Cable layout | Electrical resist. C.C. at 20ºC (*) ohm/km | External diameter (mm) | Weight (kg/km) | Bend Radius (mm) | Max. Pulling Tension (daN) | Code | ||

|---|---|---|---|---|---|---|---|---|

| Power Conductors Nº x mm² | Grounding Conductor Nº x mm² | Control Conductors Nº x mm² | ||||||

| 3x25 | 3x6 | -- | 0,78 | 29,7 | 1350 | 178 | 465 | FFfr 3250 0360 UAm(Th)UAm |

| 3x35 | 3x6 | -- | 0,554 | 30,9 | 1643 | 185 | 615 | FFfr 3350 0360 UAm(Th)UAm |

| 3x35 | 1x16 | -- | 0,554 | 31,2 | 1645 | 187 | 605 | FFfr 3516 UAm(Th)UAm |

| 3x35 | 1x16 | 2x10 | 0,554 | 33,8 | 1807 | 203 | 705 | FFfr 3516 2100 UAm(Th)UAm |

| 3x35 | 1x35 | -- | 0,554 | 32,8 | 1861 | 197 | 700 | FFfr 4350 UAm(Th)UAm |

| 3x50 | 3x10 | -- | 0,386 | 35,4 | 2227 | 212 | 900 | FFfr 3500 3100 UAm(Th)UAm |

| 3x50 | 1x25 | -- | 0,386 | 35,7 | 2256 | 214 | 875 | FFfr 5025 UAm(Th)UAm |

| 3x50 | 1x25 | 2x10 | 0,386 | 37,3 | 2339 | 224 | 975 | FFfr 5025 2100 UAm(Th)UAm |

| 3x50 | 1x50 | -- | 0,386 | 38 | 2568 | 228 | 1000 | FFfr 4500 UAm(Th)UAm |

| 3x70 | 3x16 | -- | 0,272 | 40,6 | 2942 | 244 | 1290 | FFfr 3700 3160 UAm(Th)UAm |

| 4x70 | -- | -- | 0,272 | 43,2 | 3454 | 259 | 1400 | FFfr 4700 UAm(Th)UAm |

| 3x95 | 3x16 | -- | 0,206 | 44,8 | 3850 | 269 | 1665 | FFfr 3950 3160 UAm(Th)UAm |

| 3x95 | 1x95 | -- | 0,206 | 49,2 | 4455 | 295 | 1900 | FFfr 4950 UAm(Th)UAm |

| 3x120 | 3x25 | -- | 0,161 | 52,8 | 4920 | 317 | 2175 | FFfr 31200 3250 UAm(Th)UAm |

| 3x120 | 1x70 | -- | 0,161 | 51,1 | 5063 | 307 | 2150 | FFfr 12070 UAm(Th)UAm |

| 3x120 | 1x70 | 2x16 | 0,161 | 50,8 | 4990 | 305 | 1960 | FFfr 12070 2160 UAm(Th)UAm |

| 3x120 | 1x95 | -- | 0,161 | 51,8 | 5105 | 311 | 2275 | FFfr 12095 UAm(Th)UAm |

| 3x185 | 3x35 | -- | 0,106 | 58,8 | 7209 | 353 | 3300 | FFfr 31850 3350 UAm(Th)UAm |

| 3x240 | 3x50 | -- | 0,0801 | 67,3 | 9543 | 404 | 4350 | FFfr 32400 3500 UAm(Th)UAm |

(*) The informed electrical resistance corresponds only to the phase conductors